Posts by mycontrolroom

Workshop Coming Up in Prescott, AZ

Control Room Evolution

It never ceases to amaze me when I walk into a control room and see environmental conditions that are contributing to poor operator situation awareness. A vast majority of our present-day control working environments are a result of evolving a room that was based on 1950s design technology. Some of the control room renovations we…

Read MoreField Operations With Ian Nimmo

Field operations is about making sure people do things correctly the first time. We look at the quality of what the operator does, what activities they do, how they work as a team. We are taking best practices that have been identified and applying them, helping you fix problems before they begin. Field operators and…

Read MoreIt Is Well With My Soul This Thanksgiving

Dear Friends, One of the delights of owning your own business is the relationships you build with people all around the world. Thanksgiving always reminds me of this. I am grateful I work in an industry that fosters good working relationships and the formation of many friendships. I am grateful for the opportunity to have…

Read MoreSinclair Testimony

At our refinery, prior to engaging in Alarm Rationalization, our alarm was practically useless. Our directive on alarms was to configure everything, and if we did not have any suggestions on setpoints, the alarms were configured at range. Sinclair Testimony After rationalizing our alarms, we reduced alarm instances by almost 90%, and our board operators…

Read More3 Things UCDS Is Doing Right Now

Hello, Steve here to talk with you about some interesting things UCDS has been doing in the last two years. As you know, Covid has impacted not only our industry but the entire globe. As businesses started opening up again, the main question plants had was can we do more with less staff. Some plants…

Read MoreGap Analysis with Ian

In this video, Ian discusses gap analysis. Businesses need a good philosophy before they can begin, and gap analysis can be applied in different areas. Compare what your company has with the international standards and begin to understand what the problems are, identify the gaps, and come up with a plan to fix them. The…

Read MoreBest Practices and International Standards

Best Practices and International Standards with Ian Nimmo. While no one person can define what best practices are, we can look at research from the past 30 years and find best practices. Best practices can be found in international standards, guidance documents, and communication in the industry regarding what’s not working versus what’s working very…

Read MoreOperator Training Development

Operator training development with Ian Nimmo. We must identify roles and responsibilities, then put together job performance profiles. This helps us identify what skills are needed in order to do the job. Looking at every aspect of the job, we then create a program for new people coming into the industry as they progress through…

Read MoreWork Team Design

Ian Nimo discusses Work Team Design. User Centered Design Services has developed an assessment methodology that compares the current operations Work Team Design to industry Best Practices. Our review includes the Work Group Structure, the Work Group Interaction, and the Management Structure and Philosophy. Our process can be applied to current staffing at a site…

Read MoreControl Room High Performance HMI

Ian Nimmo discusses control room high-performance HMI. Most people only use HMI, resulting in over-using colors, glaring screens, and information being displayed incorrectly. Our retention is focused on how an operator detects a problem. We want to be able to detect the moment we leave normal operation. We need to define what is off normal,…

Read MoreAbnormal Situation Management

Ian Nimmo discusses Abnormal Situation Management. From a production perspective, how do we keep processes within normal operating limits and how do we determine normal operations? Abnormal situation management is when a process begins to function outside those limits, and an operator must step in to help the automation system. Today, HMI tools are needed…

Read MoreStaffing Studies

Ian Nimmo discusses how workload staffing studies are becoming increasingly important in the industry and looks at the economics of business models post COVID. In the past, time and motion studies were used to analyze staff efficiency, but that no longer works. After gathering this information, we can get a good understanding of the operator’s…

Read MoreMinimizing Risks & Consequences of Organizational Changes

“We have 8 control room operators. The union says we need 8, but we believe we only need 6. So, we outsourced a staffing study to measure the workload of each position to see if we could consolidate a few positions into a single position and where those responsibilities could be absorbed. This project was…

Read MoreSituation Awareness

Ian discusses situational awareness. Most people believe situational awareness is knowing what is going on around you at all times. But there’s more to it. It’s knowing what was going on around you 30 minutes ago, what happens 30 minutes from now, etc. This gives the operator the complete picture. A control room provides a…

Read MoreManagement of Organizational Change

Management of Organizational Change with Ian Nimmo Management of Organizational Change (MOC) has been a challenge in today’s workplace and has been a major contributor to most accidents. However, the United States Regulator OSHA has issued a Process Safety Management requirement and spelled out what is expected of industry and how to comply. Many companies…

Read MoreOther Resources from UCDS

Control Room HMI Design

President and CEO of UCDS Ian Nimmo discusses the history of HMI (Human Machine Interface) Design. He explores the evolution of HMI starting back from the processing industry when operators used analog instrumentation on control panels, all the way to describe the benefits of modern HMI today. The ultimate goal of HMI today is…

Read MoreConsolidating 2 or More Operator Positions into 1 Position

Don’t change workload without knowing the risks: We are often asked to identify where operator responsibilities can be moved from one position to another. In some cases, clients believe they can combine 2 operator positions into one. We have discovered some positions can be consolidated in specific units in the plant. Keep in mind, you…

Read More24/7 Operation Control-Rooms are Starting to look like Mission Critical Operation Centers!

“Technology Alone Cannot Replace the Human Factor – Not Today” Under the best of circumstances (in the right plant) the automation system should steer the process to the best operating condition and keep things humming along. The safety system, is there to prevent incidents like a release or burst. Between these safety layers is the control…

Read MoreControl Room Staffing Studies

In this video, Ian Nimmo discusses how staffing studies are becoming increasingly important in the industry. In the past, time and motion studies were used to analyze staff efficiency, but that no longer works when an employee uses an automation system. Staffing studies consist of collecting data on the physical amount and complexity of equipment…

Read MoreOperator Management

Apart from the operator user interface and control room or field environment, is operator behavior and management, known as Conduct of Operations. This is a system of improving human performance to ensure that every task is performed correctly, every time, even when nobody is watching. This is accomplished when you put documented standards in place…

Read MoreOperator Centered -Situation Awareness- Control Rooms

This is a perfect example of a control room that was designed for situation awareness. The operator workload was analyzed to know how to balance the workload evenly and to make sure they had the right number of operators in the room. Alarm management was implemented and the displays were designed using Level 1 and…

Read MoreHappy Thanksgiving

Thanksgiving 2020 As we reflect on 2020, we find ourselves tremendously grateful for our customers and the opportunities we have to help so many. We hope that you find moments in this holiday season to experience the same. We are thankful for you. Happy Thanksgiving from all of us at UCDS.

Read MoreWarning: Non-Process People are Designing Control Rooms

Let’s talk specifically about control room design for a minute. We continue to see major problems in the control room, from poor lighting, number of and placement of screens, screen sizes, room layout, traffic flow, noise, and distractions. One of the biggest issues is screen stacking and too many screens. These problems continue to happen,…

Read MoreControl Room High Performance HMI

UCDS President and CEO Ian Nimmo explains what High Performance HMI is and why it’s important. It’s about the operator’s ability to be performant in resolving abnormal situations. Nimmo explores the four different levels that must be set for the hierarchy of an HMI system. Your attention should be focused on the ability for an…

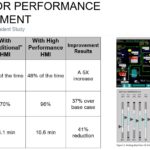

Read MoreHP Situation Awareness Displays Work!

It’s important to test your display designs and check results. Ultimately with any project we want to see an improvement in operator performance. That is why we call our displays High Performance Displays. During a study of traditional P&ID displays versus HP displays, we found that operators could detect a problem – before the alarm activated,…

Read MoreLevel One Operator Display Explained

This is a very simplified explanation of what a properly designed level one display can do. For ease of understanding, we performed an operator task analysis to identify the most important information that was scattered on many different displays and we combined that information into a simple list. The idea, is turning critical operator data…

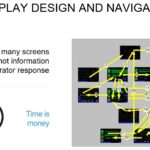

Read MoreOperator Display Navigation (let’s clean it up)

We analyzed the number of moves an operator makes as he navigates from display to display, a common practice during start up and when troubleshooting abnormal situations. The operator is looking for information on multiple screens. In this scenario, the operator viewed 28 screens during a start up, looking for information that is scattered on…

Read MoreVideo Presentation By Ian Nimmo: Operator Centered Control Rooms

Operators – alarms, displays, screens, glare, fatigue, distractions, training, data overload, etc…how do we manage control rooms and improve performance? Check out this recent video: https://register.gotowebinar.com/recording/recordingView?webinarKey=7776801068881362699®istrantEmail=csalera%40mycontrolroom.com smaddox@mycontrolroom.com / www.mycontrolroom.com / 512 630 3401

Read More