Posts by mycontrolroom

The Impact of Fatigue in a Control Room

UCDS President Ian Nimmo explains the impact that fatigue can have in a control room. He describes what it is, and how UCDS can help you avoid fatigue for your operators. There are fatigue counter measures your company can take, that UCDS can assist in. Examples of measures include taking breaks, getting fresh air, and…

Read MoreThe 3 Ingredients for Successfully Designing Level One and Two Displays

Operators possess the ability to optimize the process while monitoring multiple variables on the control system. The operator is expected to maximize efficiency and output, often working with outside operators to achieve these goals. We rely on them to detect subtle changes in a sea of information. We have interviewed thousands of operators and we…

Read MoreCosts Associated with Poor Situation Awareness and Too Many Alarms

Nuisance alarms contribute to – poor control and wasted energy – Standing alarms = feedstock expenses, containment loss, and an increase in utilities – Missed alarms = wear and tear on equipment, increased maintenance costs, and equipment damage – Critical alarms = unplanned downtime, Injury or death, or environmental violations. Alarms are a safety layer…

Read MoreOperator Performance: A Return on Investment

So if we invest in our operators, where is the ROI? Well, Operating outside equipment and process limits is costly and risky. In the above image, focus your attention on the dotted line where the fault occurs. There is a problem, the system takes some time to generate an alarm (the problem continues to grow) then…

Read MoreOperator Centered Situation Awareness Control Rooms are Designed from the HMI (Operator Displays)!

Perform an operator Task Analysis to determine what the operators responsibuilities are and what the workload consitis of. Then design the displays using the Level 1 through 4 hiarchy. Once you know eactly what information the operator requires and the best way to display the information (not using data) using analog objects which provide the…

Read MoreAlarm Management Workbook

Ian Nimmo discusses the new workbook on alarm management that UCDS will be releasing soon. It will cover the main principles about what “good” looks like from an alarm management perspective. It will also cover the life cycle model, alarm philosophies, as well as how to identify, rationalize, implement, and maintain an alarm. This is…

Read MoreOperators and Abnormal Situations

Operators are eyes and ears of a process, like pilots, they have to manage multiple instruments at the same time. They have to be positioned to resolve issues before they escalate and become catastrophic, if we address human factors in their displays, alarms, consoles, and work environment, we can address and enhance situation awareness. To…

Read MoreControl Rooms, Displays and Screens (should be an integrated design)

So, what do operator do? Ultimately, an operator’s job is to optimize the process, maintain product quality, intervene when needed, ensure safety and production goals are met, while complying with regulatory requirements. We must think of operators with the same value and respect that we give pilots. In fact operators are much like pilots, they…

Read MoreShift Handover / Turnover is Still a Major Issue in our Industry…

Achieving operational excellence is the ultimate objective, this is a moving target, but we can get close if we can change the culture! To do that you have to focus on the workers. Many organizations have forgotten about the human factor. Human performance has taken a back seat, in the past organizations spent millions of…

Read MoreGaps in Conduct of Operations

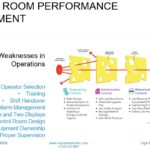

To help operators respond to alarms and manage abnormal situations quickly and correctly, they have to be vigilant, competent, responsible, and predictive. We must identify the gaps in operational standards and behaviors and improve Conduct by putting the right management systems and tools in place. The-end-result will be, High performance operators and supervisors that meet…

Read MoreProcess Operations is in Need of New Operating Standards and Management Systems – Your Best People are Looking to Retire or Switch to Another Company

Safety, Reliability, quality, and profitability goals are driven by upper management, they want to lower operating costs, increase profit, and focus on safety – so they’ve made large investments in automation to achieve these goals. The missing link, however, is the small investment made in human factors and operational conduct. Plants and Pipelines will be…

Read MoreAbnormal Situations in the Control Room

President of UCDS Ian Nimmo explains abnormal situation management. From a production perspective, how do we keep processes within normal operating limits? Abnormal situation management is when a process begins to function outside those limits, and an operator must step in to help the automation system. Today, HMI tools are needed to give operators indication…

Read MoreOperator Centered Control Rooms

What do all control room operators have in common? Technology advanced and the human factor was forgotten, but they all do the best with what they got. Technology, in many cases, made life worse for operators. They work in a position where situation awareness is critical yet we keep adding screens and data thinking it…

Read MoreSelecting and Training Operators

Operators are often selected based on years of experience and are rarely tested for managing large amounts of data and hundreds of unique scenarios. Rarely do they receive formal process condition training using a formalized classroom instruction course with professionally prepared training manuals and tests. Most companies rely on experience and move people from one…

Read MoreControl Room Alarm Management

In this video Ian Nimmo, CEO of UCDS, discusses why alarm management is so critical to the control room. He explains why major accidents have been attributed to the alarm system. In many situations, the operator missed important events because they were overwhelmed with alarms and did not have the opportunity to go through the…

Read MoreNavigating Control Building Policies and Procedures Post COVID-19

As the world adapts to a new norm resulting from the COVID-19 pandemic, many Process Control operations have been developing work policies to further mitigate the spread and outbreak of the virus. While 24/7 command and control environments contain similar working routines as compared to typical office environments, Control Buildings require many strategies that go…

Read MoreControl Room Design

In this video, Ian Nimmo of UCDS discusses the importance and complexity of control room design. It’s much more than simply hiring an architect to design a control room. Nimmo describes just some of the considerations that need to be made when designing a control room. Beyond architecture, there’s the layout, communication between users, flow…

Read MoreWhy choose UCDS?

Ian Nimmo, President and CEO of User Centered Design Services, discusses the company’s history. UCDS has been in existence for over 20 years. Our foundation was at the abnormal situation management research consortium where Nimmo was the program director. Now, operations are the main focus of UCDS, both in the control room and in the…

Read MoreDo you know your Process’ Sacred Six?

My first lesson in Human Factors was a memorable one as evidenced by the fact that it has stuck with me for over 20 years. As I remember the talk during World War II, the fatality rate of US Navy aviators, due to pilot error in training and in action, had become unacceptably high.…

Read MoreIf one of your operators misses an alarm because there are too many, what is the best solution?

As a former Process Control Manger, I have had this discussion more times than I can remember, and it has generally been with people who I would otherwise consider intelligent. Thinking back, I find it interesting that I never had this discussion with the person with the most knowledge of the situation, the console operator. So, what is…

Read MoreHow to Create Control Room Design Specifications

The basis of any control room design specification should be based on the International Standard for Ergonomic Design of Control Centers ISO 11064. The document is in 7 parts, part 6 being the main specification. Before you can use this part 6 of the standard much work needs to be done clarifying the control room…

Read MoreUnderstand the Control Room Design Layout Requirements

The control room design layout is conceived during the Conceptual Design Phase of a control room project and formalized during the Detail Design Phase. The requirement comes from the initial data collection phase capturing and analyzing functions and tasks, developing room layouts, furnishing designs, displays and controls, and communication interfaces to necessary to satisfy needs…

Read More5 Ways to Better Equip Your Control Room Operator

In control rooms are day-to-day issues and systems that impact the performance of control room operators, the most common are defined as compromises to Situation Awareness. We will review each of the five and provide insight into practical solutions to implement them. The first is providing Adequate Information, control rooms are full of data, but little…

Read More3 Things You Didn’t Know About High Performance HMI

The High-Performance HMI is grounded in ASMTM principles. The Honeywell ASM Consortium which I used to be the Program Director and founder did extensive research into HMI graphics practices. At the time, Honeywell was locked into a development path which was not graphics friendly and was before the decision to switch to a Windows-based control…

Read MoreWhy High Performance HMI Is Often Misunderstood in the Control Room

The processing industry has evolved from physical instruments on a panel to electronic physical controllers on the panel to a limited group of 8 faceplates on a black background which replicated the electronic controllers. The industry identified that this limited view did not show the context of the faceplate and relied on the operator mental…

Read MoreHow Alarm Management Could Save Your Company Millions

Alarm Management is more than just another chore companies must do to comply with Regulations, it is a great investment and has an immediate ROI when done correctly. Unfortunately, it is often treated as a chore with no ROI. Let me say first off that no plant or process is designed to run in Abnormal…

Read MoreHow to Do Your Own Alarm Management Training

Alarm management training is something that many companies skip assuming that operators will figure out how to respond to an alarm, they do this because that is the way it has always been done. As alarms get more complex, more rational, and more ways to configure them using multiple alarm modes and attributes. Some alarms…

Read MoreHow to Create an Alarm Management Policy

Alarm Management is probably one of the most written about topics in control theory and one of the best-documented methodologies covered by International and local standards and guidance documents, yet, still many companies do not know where to start or how to get a handle on a bad alarm management system. The problem stems from…

Read MoreTypes of Organizational Change Management

Organizational change can come in many forms. The most common today is workload balancing, many companies have been through the dark period of de-manning and laying the workforce off to save costs. This came after automation reduced the need for the number of outside workers. Now because of changes to equipment, shutting down some units…

Read MoreISO 11064 Is Still Crucial in Control Rooms. Here Is Why.

ISO 11064 is the only Ergonomic Standard that comprehensibly addresses the Human Factors and Ergonomics of a control room. The role of the standard is twofold, it addresses the risk to humans through Repetitive Stress Injuries or MSDs which have been identified globally to cost industry more than $508 Billion which includes human error, turnover…

Read More