Minimizing Variations in Operation and Human Performance

What It Is

Conduct of Operations and Operational Discipline: Structuring tasks in a manner consistent with the organization's risk tolerance to ensure that every task is performed deliberately and correctly, minimizing variations in performance. By "correctly" we mean, "Everyone, doing the right thing, at the right time, every time."

What It Does

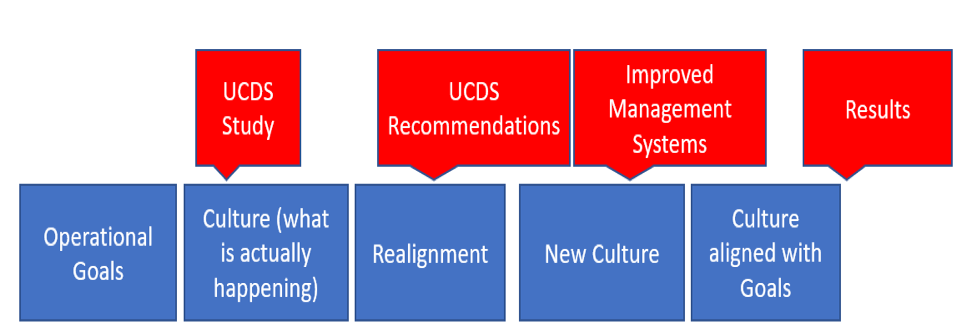

The COO&OD assessment will provide your plants leadership team with an objective third-party gap analysis that can be used to ensure a safe and profitable operation, by identifying how you can improve your conduct of operations management systems and standards. Identify how you can improve the performance of your front-line supervisors, field operators, control room operators, and support functions, such as maintenance, reliability and engineering.

What It Consists Of

The COO&OD consists of a comprehensive onsite study by two of the world’s leading experts (Ian Nimmo and Jack Pankoff) who have 50 years of experience in operational excellence / safety best practices.

The Deliverables

The COO&OD Assessment will result in a comprehensive report consisting of a summary of our findings, major gaps, safety risks, prioritized action items, best practices, recommendations, and perceived culture weaknesses. Also included will be a PowerPoint presentation and an onsite review meeting to discuss the results.

COO&OD Presentation

The management presentation will inform and educate your Leadership Team on what best in class looks like. It will help break down barriers to change and develop continuous improvement practices. This study will evoke a culture change and bridge communication gaps between management, the control room, the field, engineers, and maintenance personnel.

Benefits

- Reduces risk and enhances operational integrity

- Operational objectives aligned with each department

- Goal alignment from the top down

- Communication improved between departments

- Improved Process Safety and Personal Safety Management

- Improved execution of the production plan

- Improved mechanical integrity

- Improved Employee Performance and Operational Discipline

- Software and hardware solutions identified to improve human performance and reduce human error

Schedule Consultation

Simply fill out the form and we will be in contact with you shortly to schedule a phone or web conference to answer questions and discuss how we can help your organization.