Background

Proper HMI design can reduce operator workload, improve situational awareness, and aid the operator in preventing minor deviations from becoming major incidents. Well-designed HMI also works hand-in-hand with Alarm Management initiatives, since better presentation of information to the operator improves overall situation awareness. This helps offset the perception operators frequently have that elimination of alarms from the DCS will reduce their ability to track the status of the plant.

Recent research has identified that well-implemented HMI can improve operator performance in problem detection and resolution by as much as 25 percent. This reduces the amount of time the plant is running at less-than-optimal efficiency, thus improving the bottom line. This also reduces operator stress and improves employee relationships.

If any of the following seems familiar, your HMI needs improvement:

-

Operators claim they need ten screens to operate the plant.

-

Graphics appear cluttered.

-

Graphics are more colorful than a carnival.

-

During an abnormal situation, operators rapidly jump between screens, searching for the information they need.

-

Graphics are developed page-for-page from the P&IDs.

-

Graphics do not incorporate the latest cognitive processing research.

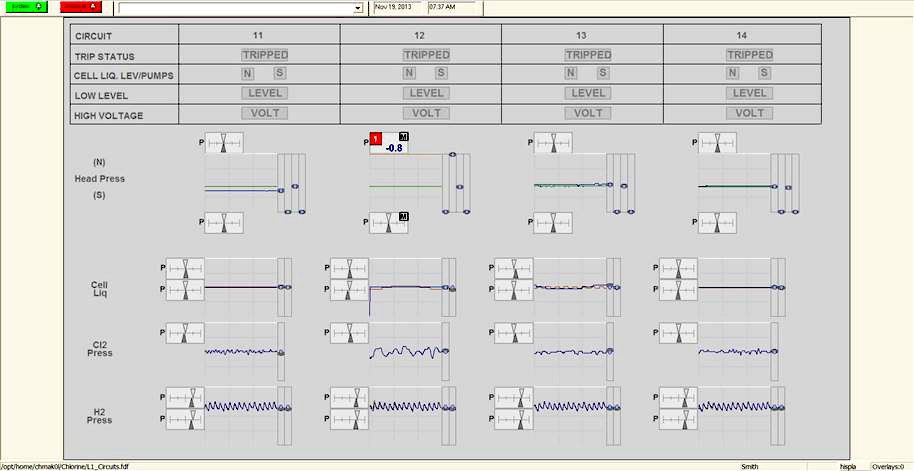

Example: Level One Overview Graphic

This is an example of a Level One Overview Graphic showing the operator the status of his critical processes, allowing the operator to easily detect and predict potential issues. Color and shape is used to capture the operator's attention. Each area shows the current status, operating limits and proximity to alarming. Trends are used to monitor the past, present and future. Designed alongside the operator, we focused on critical alarms and the worst situations that this operator could have, then we designed the graphic so that the operator could easily scan the image and know precisely where the problem is manifesting.

Well-implemented HMI can improve operator performance, increase efficiency, reduce operator stress and employee relationships, and increase ROI.

Service Description

UCDS has extensive expertise in the following HMI standards, regulations, and best practices:

- ASM Consortium Effective Human Machine Interface Guidelines (guideline)

- ISA-101.01 – Human Machine Interfaces for Process Automation Systems (future standard)

- API 1165 – Recommended Practice for Pipeline SCADA Displays (recommended practice)

- NUREG 700 – Human-System Interface Design Review Guidelines (guideline)

- EEMUA 201 – Process plant control desks utilizing human-computer interfaces: a guide to design, operational and human-computer interface issues (guideline)

- ISO 11064 part 5

UCDS leverages this expertise to offer a full line of consulting services to evaluate your current plant condition, make realistic and achievable recommendations for improvement, and aid you in the implementation of those recommendations. Our set of Human-Machine Interface (HMI) services are integral to providing guidance on industry standards and best practices.

UCDS offers the following HMI services:

- Human-Machine Interface Gap Analysis: Assess the current state of your site's Human-Machine Interface, benchmarking it versus ASM® recommendations and industry best practices. Following the site visit, UCDS will generate a report detailing the current state of the site's Human-Machine Interface versus best practices. The report will also include many recommendations to be considered to improve your site's HMI.

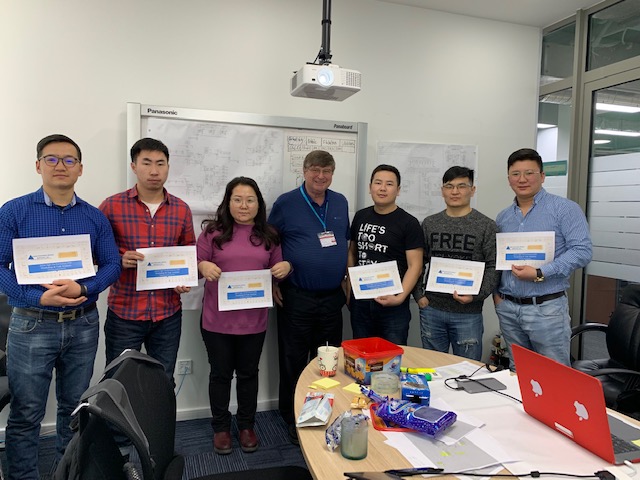

- High Performance Graphics Workshops: Educate facilities on best practices in Human-Machine Interface design.

- Overview Display Design: UCDS utilizes a task analysis process, which includes input from operators and managers, to determine the requirements for the overview displays.

- Style Guide: UCDS will develop a detailed Human-Machine Interface style guide, covering all aspects of best practices in situational awareness and cognitive processing, including conducting training for proper implementation at your facility. The guide covers items which govern the look and feel of the user display: navigation, display hierarchy, use of colors, window management/number of screens, integration of trend and alarm information, integration of other information, identification of specific display objects, and intra-display communication and coordination.

- Migration Strategy: UCDS assists clients in making more cost-effective changes outside the traditional DCS upgrade project. This migration strategy sets a path forward for implementation of best practices over time, within normal system maintenance budgets.

- Object Library: High-performance graphics (operator displays) using situation awareness objects will be the new standard per ISA 101. We have an Object Library that has proven to be the best in the industry. We designed each object for each piece of equipment with detailed information showing set points, alarming, running, stopped, shut down, etc. Our objects are proven to improve operator detection, increase situation awareness, and improve abnormal situation management. Our objects make shut down and start-ups safer. We use our object library design document as a template and a few days on site to create your own custom objects based on your equipment, showing how they attract attention and provide guidance. This document is used as a reference guide for designing new graphics, it’s used as a training tool, and it will evolve and provide an MOC for future design changes. Before you change your graphics, we highly recommend the users (operators and controllers) take ownership of the object designs. Our Object Library workshop brings the users and the objects together.

Check out the new book by UCDS, Inc. President Ian Nimmo, Operator Effectiveness and The Human Side of Error. Click here.

For additional information, please e-mail us at sales@mycontrolroom.com.

Schedule Consultation

Simply fill out the form and we will be in contact with you shortly to schedule a phone or web conference to answer questions and discuss how we can help your organization.