User Centered Design Services Inc. would like to announce the return of Dave Lee to UCDS.

Dave has been hired as President and will be working hand in hand with Ian Nimmo and the UCDS family. Together Dave and Ian will be tackling daily operations and fulfilling customer requests for improved staffing arrangements, alarms, High Performance HMI displays, ergonomics, and control room designs that are tailored for process operators. Dave started his career in engineering in 1985 when he graduated from the University of Birmingham with a degree in chemical engineering. He has since worked in industry as an engineer and manager and across the world as a consultant. Dave met Ian when he was a customer in 2002 while working for LyondellBasell as the Plant Automation Manager. Over their shared British origins Ian and Dave hit it off and have been friends and working partners ever since.

- Dave brings 38 years of experience in automation, control room operations, operator user interfaces, control room technology, and automation project leadership skills.

- Dave is a Chartered Engineer and Fellow of IChemE.

- Prior to rejoining UCDS Dave worked with Emerson the past 5 years as an operator performance and solutions consultant.

- He is a leading figure in alarm management, display design, operator staffing, automation engineering, and an operator effectiveness expert.

- Dave is an active member of ISA where he has held various leadership roles and is currently Chair of the S&P Board. He is an active member of several standards committees.

- He also represents the US on IEC 63303 as an HMI SME.

We are grateful and excited to have Dave join us again at UCDS!

"Need more from your process? Invest in your people!"

By Stephen Maddox, Business Development Manager, UCDS

"It's been studied and reported that companies’ operating costs are increasing. Many would believe that the majority of operating costs come from maintenance, utilities and equipment management. But 82% of the money goes to payroll: the workers. Yep, you heard that right. The people are the highest operating cost. Of course they're a critical component, but—are they really that important?..."

Interested In Our LinkedIn Group?

Join the discussion and network with members from all over the world. Learn from some of best minds and innovators in the industry.

We provide a complete Operator Centered Situation Awareness Control Room Methodology.

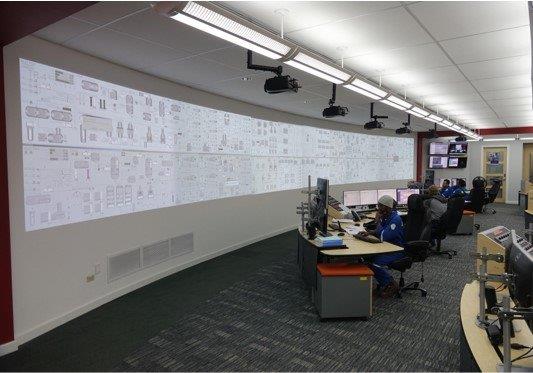

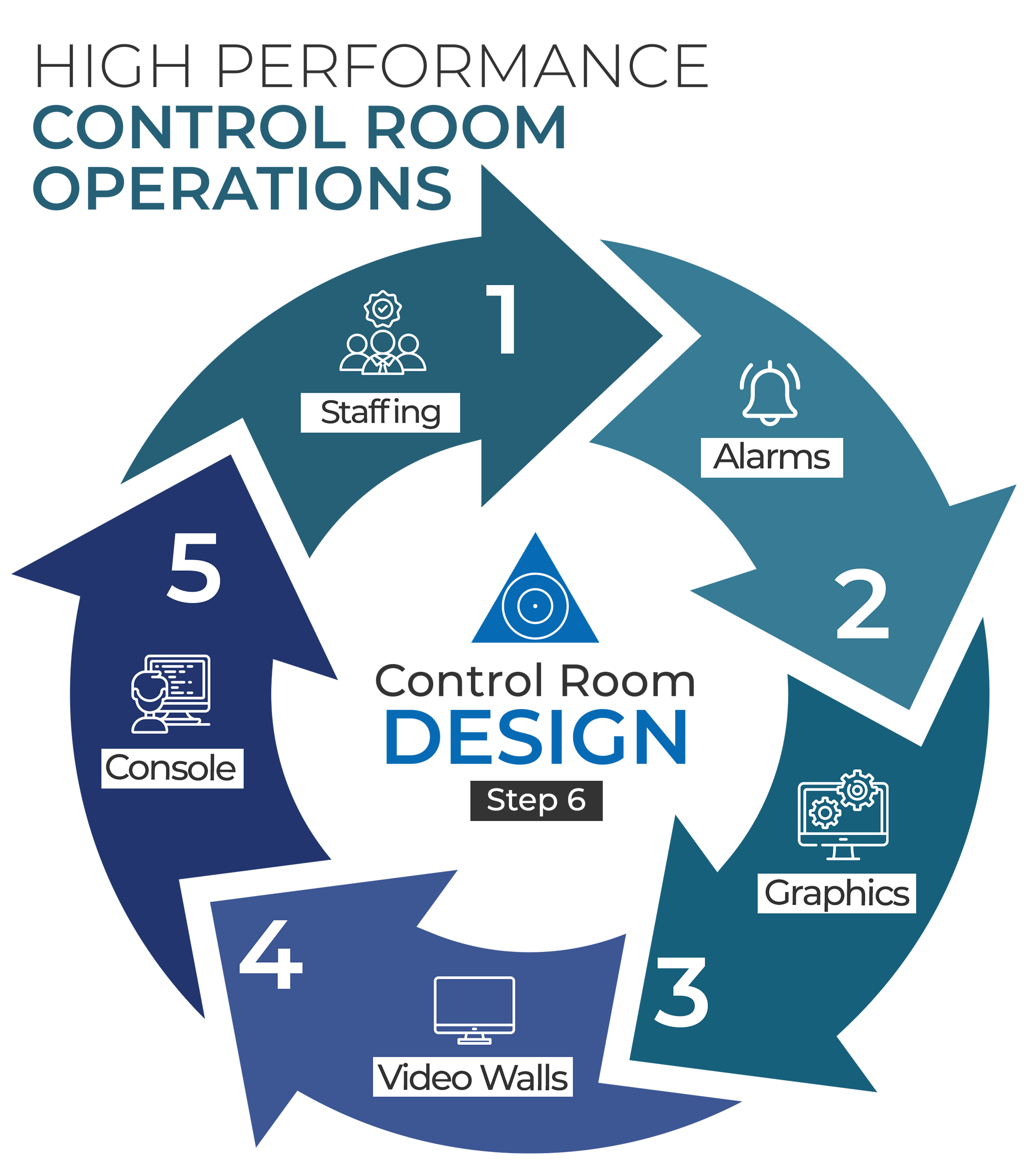

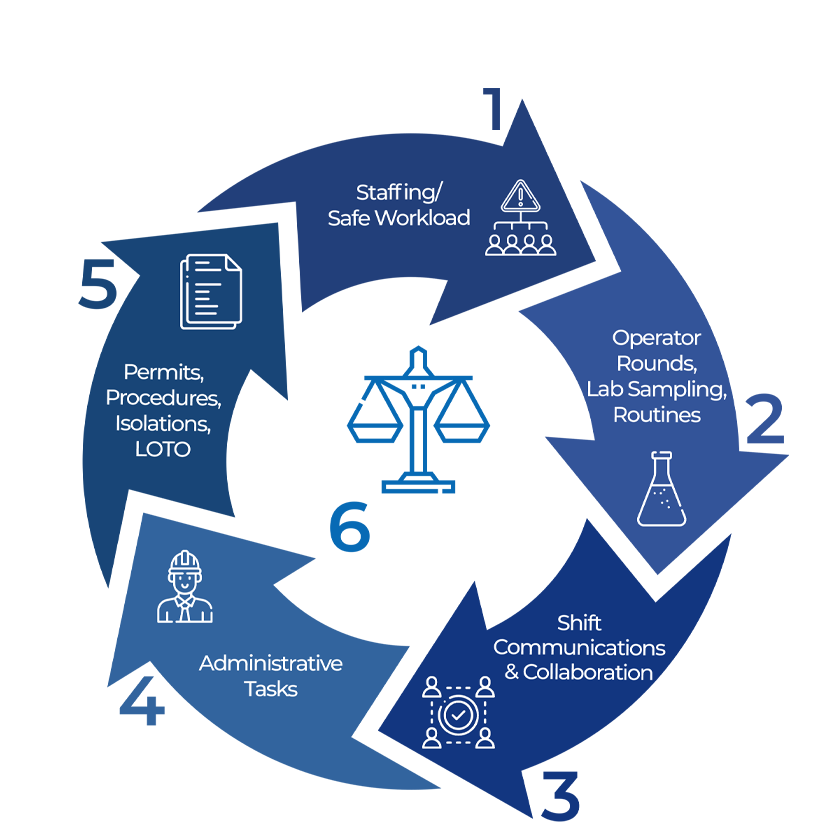

Starting with a workload / operator staffing assessment - ensuring operators can respond to critical alarms in a timely effective manner, then developing an alarm management standard, next designing an operator user interface (displays) and screen design layout to enhance situation awareness, then designing a console specification, and last we integrate everything into the design of the control room.

Situation Awareness is an Operator Requirement – it is achieved when you integrate all 6 of the following phases into an Integrated Human Factors Solution: