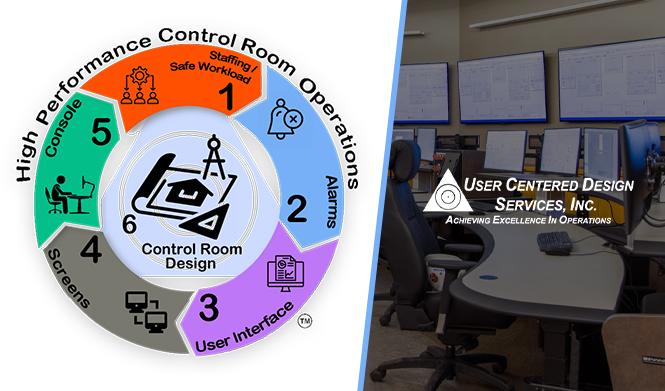

The 6-Step Methodology

UCDS uses a 6-Step methodology to design a User Centered Control Room to enhance operator performance. The goal is to keep the operator’s attention engaged without relying on alarms. Our methodology is a phased approach, each step in our methodology leads into the next step. Each step has an impact on the design of the control room. We are the only company in the world that uses this 6-step integrated solution to incorporate all user requirements into the design. This method puts the focus on the 3 major Operator pillars: Detect, Diagnose, and Manage all situations.

Key performance factors include:

Human Factors, Operator Vigilance, Situation Awareness, Discipline, Fatigue and Health, Distractions, Data Overload, Nuisance Alarms, Data that needs to be converted into information, High Workload, and Poor Operator Response during upsets. Situational Awareness is an Operator Requirement – it is achieved when you integrate all 6 of the following phases into an Integrated Situation Awareness Solution:

- Operator Staffing & Workload Assessment: We assess your operator tasks and measure the workload for each operator position to determine if the operators can safely detect, diagnose, and respond to abnormal situations. We assess the operator’s management systems, environment, and job duties. We developed the Automation Index Modeling (AIM) tool that scores the complexity of all the equipment under the operator’s responsibility. We assess the operator tasks to determine how to balance the workload evenly across each position. We provide a workload score for each position based on the complexity of the equipment, automation performance, and the required operator tasks. We examine where positions can be consolidated, if there is a need to add a position, and we examine where responsibilities can be moved to reduce workload. During this study, we also determine what operating practices are not best in class, we examine the overall Conduct of operations, as well as the culture and the discipline of the operators. This is a detailed assessment of your staffing, organization, and work team design. Workload impacts operator performance and number of operators required impacts the control room layout and size.

- Alarm Management: We develop an alarm management team – site standard, site expert (an assigned position / for ownership & responsibility) and develop a program for managing and sustaining the alarm system (ISA 18.2 & IEC 62682). We examine ways to provide alarm information in the displays, audio, and screens. Alarm management has a major impact on the display design, screen size and location, and will impact the design of the room.

- High Performance Displays: We develop an HMI site standard and style guide. We design operator displays for situation awareness based on prioritized events that require operator attention using a Level 1 through 4 hierarchy: (ISA 101). Displays effect the screen size, layout, number of screens required, screen placement and will impact the size and design of the operator consoles which will impact the design of the control room.

- Ergonomic Screens / Video Walls / Lighting: We assess the operators visual needs: Number of screens, screen size, screen layout for the console and if screens should be located on walls. We determine the best way to display the graphics and other interfaces they use. We often see operators with 8 or more screens on the desktop and other screens located on the wall, with no organization or grouping philosophy. We implement glare reduction solutions and ensure the displays and alarms are presented ergonomically and effectively. We provide a lighting solution with considerations for day shift and recommendations to reduce blue light during the night shift. We address Circadian rhythms, fatigue mitigation, vigilance, worker health and the ISO 11064. Vendor recommendations will depend on the needs of your operators. The number of screens, screen size, and screen location (wall or built into the console) as well as the lighting / ceiling will affect the design of the room.

- Console Design: We assess operator tasks to determine a user centered workstation to fit the console to the worker. We integrate the screen layout into a customized console design spec, manage the console vendor, and oversee the console installation. (ISO 11064). The console design will impact the entire layout, size, and overall flow / & design of the roo

- Control Room Design: Our architect combines all the operator requirements captured from steps 1-5 into a conceptual design for your review. This concept design is reviewed, and changes are captured for the final control room design. A 3-D rendering will be sent along with a detailed report capturing all the information and recommendations for the control room; addressing risks associated with fatigue, situation awareness, predictability, ergonomics, and human performance / behavior (ISO 11064). This is a user centered methodology that puts the operator’s needs, health, and performance above everything else.