High Performance HMI

This month’s focus has been High Performance HMI for me, a lot of new interest. I joined other experts at the Emerson Exchange to discuss an alternative design without dependence on P&ID’s and PFD’s. So, what is the alternative? If anyone would like a copy of my slides let me or Steve Maddox smaddox@mycontrolroom.com know and we will send you a copy. In the presentation I stated that:

An interface should provide the operator with the following information:

- After initiating an action within a system the operator should be clearly informed of the result of their action.

- If there is a delay in the system that prevents the operator from being informed of the result of his/her action, the system should inform the operator of this fact.

- If an action is made in error then it should be possible to reverse such an action where it would not be detrimental to plant safety to do so.

- The system should inform the operator of any deviations from safe operating levels.

- The role of the HMI is to transform data into information and put information into context.

I then went on to describe three different techniques for achieving these goals: Hierarchical Task Analysis (HTA), Timeline Analysis which is a powerful tool we use for Operator Workload Studies and Management of Organizational Change (MOOC), and Link Analysis another helpful tool used during the MOOC methodology that we teach customers to use.

This approach has a bigger payback than just the HMI requirements capture it also provides insight into developing good procedures, identifying training requirements, insight into investigating human error, etc.

We are currently preparing a new workshop for customers on this approach. Combined together with our current Situation Awareness and High Performance HMI Workshop will be a powerful addition and a great initiative for our customers to get that big ROI I keep telling people about.

I am delighted that many customers are embracing the ISA SP101 life cycle model and are using our HP HMI Philosophy and Style Guide Document. We are also doing gap analysis against our criteria of what good looks like from the Philosophy perspective and the best practices we have identified.

I will soon be speaking at the Yokogawa conference as a keynote speaker on HP HMI. Following is my abstract:

Description: Control systems have improved plant operations, but what happens when they fail to keep the process under control? We have a backup, the control operator whose role is to manage abnormal conditions and pick up the workload.

Is the current generation of operators as capable of responding to abnormal conditions as the older ones? Operators used to be proactive, lived with few alarms and managed the process by proactively monitoring trends. The trends were organized and calibrated to provide easy pattern recognition of change and were grouped by operator tasks. Operators trained in this environment had a deeper knowledge and better mental model of the system than today’s operators who run the process by alarms.

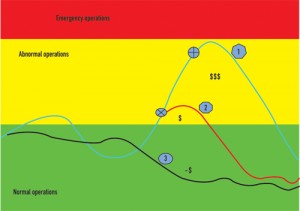

For a “Highly Effective” HMI, we expect the operator for a majority of the time to monitor trends and be proactive resolving problems during normal operations. In the event of an alarm, the HMI would provide objects or tools that will pop-off the screen to help in quick resolution of the move outside of set operating limits, minimizing the time the process spends in an abnormal condition.

For additional information on High Performance HMI, see my article in Control Global this month: http://www.controlglobal.com/articles/2012/nimmo-best-practices-high-performance-hmi-design.html.

Many customers are taking advantage of year-end funding to invest in their HMI. We are running out of availability this year for workshops but we can turnaround Philosophy and Style Guides for most DCS vendor equipment. We are prepared to book workshops now for next year allowing you to pay this year as part of the document deliverables.

This has been a crazy year for UCDS. Dave is holding up well to the pressure. He has done more staffing assessments this year than since we started as a company back in 2000. We have done a lot of new control rooms and quite a few refurbishments to existing control rooms. I had the pleasure to be in Colorado Springs reviewing four control rooms for the public services. They have initially done a really good job, but as time goes by things change, equipment needs updating and the opportunity to take advantage of new technology keeping companies on the competitive edge.

We have many customers looking to enhance their shift handover procedures and follow some of the Recommended Practices identified in the API documents; others are focusing attention on fatigue and fatigue countermeasures. We have great solutions for both these topics. For more details please contact Steve Maddox.

Our training and manuals team has just won a significant order from the customer they have been working for all year, which is the best compliment a team can get. Well done Harry, Ray and Bob. We are also looking at some new installations or upgrades to DCS and the team will be producing training for operators and engineers on the system and specific training manuals for the new HMI. The team specializes in process training but have the competency to provide DCS and HMI training systems.

UCDS is looking to hire two new employees and are taking applications now from experienced engineers and also young human factor engineers who want to learn from the best.

My good friend and colleague Jack Pankoff is still working in collaboration with us on several projects and he is about to launch some new workshops which yours truly will be standing side-by-side with him. Check out his latest on-site workshop, “Road Map to Operational Excellence in the Process Industry”, http://www.proexcinc.com/downloads/PEi_OperationalExcellence2012.pdf. Someone called me the other day and asked me if I wanted a “Magic Jack” I told them I already had one and he was irreplaceable!

The only way to make money is to have operators that are pro-active as shown in #3. If a catastrophic failure occurs operators must respond as shown in #2. We never want operator’s being reactive and taking extreme lengths of time to detect, diagnose and recover the process back to a normal state. Many companies today operate using the #3 model and it costs them their ROI, plus other major losses. It impacts equipment reliability, quality, production capacity and produces waste and other losses including increased energy costs.

Join us and our successful customers who want to live in “Normal Operations”, make alarms a rare occurrence rather than the norm. We promote pro-active operations and achieving excellence has been our motto since we started in business.