The Importance of Operator Staffing Studies for Control Rooms

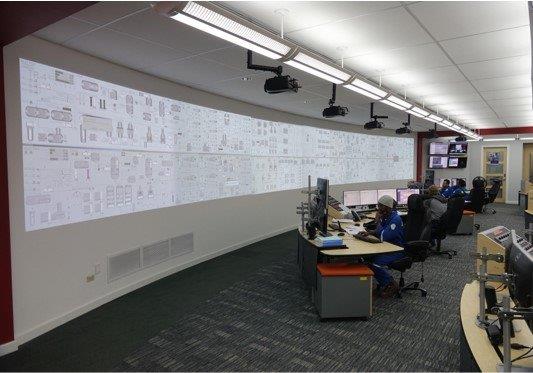

The heart of every efficient control room is centered around well trained, competent, and vigilant operators. Ensuring you have the right number of operators at the right time is not just about meeting regulatory requirements, it’s also about ensuring the smooth and efficient operation of your facility. This is where Operator Staffing Studies come into play.

What are Operator Staffing Studies?

Operator Staffing Studies are comprehensive evaluations designed to determine the optimal number of control room operators needed to run operations safely and efficiently. These studies measure various factors that contribute to operator workload such as equipment complexity, fatigue levels, DCS performance, and interactions between process units. Every piece of equipment is scored, including alarms, operator moves, loops, and feeds. This is a detailed study that takes everything into account to show you where positions may be overloaded or underloaded.

Why are Operator Staffing Studies Important?

Inadequate staffing can lead to operator fatigue, decreased morale, increased error rates, and even safety incidents. Conversely, overstaffing leads to unnecessary costs. Workload studies uncover variations in performance like operators that operate in manual because of automation issues. Here are some reasons why Operator Staffing Studies are crucial:

- Ensure Safety: Overworked operators are more likely to make mistakes that can lead to safety incidents. By determining the correct staffing levels, you can ensure that operators are not overloaded and can perform their duties safely.

- Increase Efficiency: Having the right number of operators ensures that tasks are carried out efficiently. It reduces the likelihood of bottlenecks and ensures smooth operations.

- Cost Savings: By avoiding overstaffing, you can save on unnecessary labor costs.

- Regulatory Compliance: In many industries, regulatory bodies require that companies conduct Operator Staffing Studies to ensure safe and efficient operations.

Conducting an Operator Staffing Study

Conducting an Operator Staffing Study involves evaluating various aspects of your operations. Here’s a general outline of the process:

- Workload Assessment: Evaluate the complexity of the equipment and tasks each operator is responsible for. This includes both regular duties and infrequent tasks such as responding to emergencies or equipment failures.

- Fatigue Analysis: Analyze current shift patterns. Consider factors such as length of shifts, rotation patterns, and rest periods.

- Technology Review: Assess the technology used in your control room. Advanced automation can reduce operator workload, but it also requires specialized skills.

- Benchmarking: Compare the performance of your operations with similar facilities and industry pacesetters.

Recommendations: Based on the analysis, determine the optimal staffing level and perform case studies to achieve the most effective workload distribution between operators.

Proper staffing studies measure the workload for both normal operations and abnormal operations to prove if a staffing change or organizational change is safe before a staffing or responsibility is changed.

Staffing studies also look at operator tools, systems, and culture to identify where workload can be reduced to ensure critical situations are not missed. Staffing studies often uncover opportunities to improve situation awareness by reducing nuisance alarms, improving displays, and developing written training materials for the operators.

Operator Staffing Studies are an essential tool for ensuring control room efficiency and safety. They ensure that you have the right people in the right place at the right time, ultimately leading to improved operations and cost savings.

Remember, a well-staffed control room isn’t just about numbers—it’s about having a well-organized team that can work together effectively to keep operations running smoothly. Situation awareness is key and communication is vital.