Professional Achievement

This last week I received the following email:

“You are cordially invited to be our guest of honor at the annual ISA Fellows Luncheon. The luncheon will take place on Monday, 4 October at the Westin Galleria Hotel in Houston, Texas. As a guest of honor you are entitled to a complimentary luncheon ticket for you and a guest. There is no formal program at the luncheon, however each new Fellow will be introduced and invited to briefly share with attendees what you consider your most significant professional achievement.”

Wow, what a great honor, I feel really humble; this is going to be quite a day in the life of this engineer…after the lunch, the formal dress dinner, and awards ceremony! But this invitation has made me stop in my tracks. If you know me that takes some doing!

That question “what do you consider your most significant professional achievement”, set me thinking. Past projects came flooding back to me from my early days during my time with ICI where I have to admit I had the most fun and achieved some incredible things which today may seem trivial but back then were quite something.

My very first assignment on my own had responsibility which would lead to people being disciplined. This was on a small plant in Scotland, which involved re-drawing the site (in ink) after a major fire/explosion and redoing the electrical area classification and reporting none-compliance. It was my first extended time away from home and living in a small hotel for a long period. I had to rely on company standards instead of anything I had learned at college. I had to learn to get people to work with me, get me information and manage priorities. This prepared me for my own site job.

I had a good friend and a great Engineer Larry Conner who was my mentor. We did things that others could only dream of doing. We had every technology from thermionic valves to the first germanium then silicone diodes, to the very first transistors, logic circuits, and early control computers to the very first plc’s installed in the UK. That reminds me of a funny story regarding Larry, as new technology was being introduced we saw it for the first time at work. One day a rep came into the site to tell us we could replace some of the valve technology with this new semi-conductor technology.

Larry, excited by the robust and small technology, persuaded the rep to leave a sample diode with us. Larry spent the day testing the device and could not get it to work. When the rep returned, Larry shared his disgust and inability to get the device to conduct in any direction. To his embarrassment and the rep, who had to admit that he had left Larry with a wooden demo and not the real thing as they did not have any real ones delivered at that point as the technology was so new.

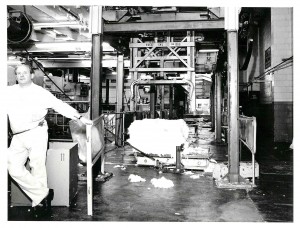

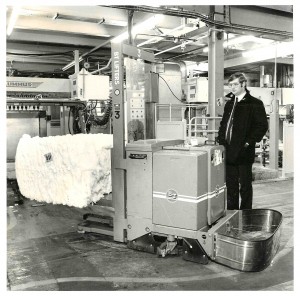

I replaced an old mechanical synthetic fiber bale handling system with a futuristic system utilizing robotic Automatic Guide Vehicles instead of an operator. With a label, a weigh scale and a John Bull kit we designed an automatic bale weighing and labeling system. Way cool! We even earned a patent for it as it was revolutionary and it worked! People and companies came from miles around to see it working, even Ford Motor Company and Black & Decker were impressed. It was a great achievement and it was applied engineering at its best.

I replaced an old mechanical synthetic fiber bale handling system with a futuristic system utilizing robotic Automatic Guide Vehicles instead of an operator. With a label, a weigh scale and a John Bull kit we designed an automatic bale weighing and labeling system. Way cool! We even earned a patent for it as it was revolutionary and it worked! People and companies came from miles around to see it working, even Ford Motor Company and Black & Decker were impressed. It was a great achievement and it was applied engineering at its best.

Yes, that was like building your very own train set. It was gratifying to see it work. A lot of things we do we often do not see anything physical from our efforts. We had many, many more exciting projects that I am proud of but the Bale Handling System (and some of the fun failures like my robot shrink wrapper which is described in a paper on our website – click here to view) is the one I am most proud of.

One of the most impressive times was one which came out of a very rare but scary series of incidents. What we achieved was incredible and we earned the title Engineer as a result of it. We at first seemed to be having a very, very bad period with failure after failure, way beyond normal including instrument failures, wiring faults, and plc’s losing their programs. We initially thought it was interference from trucks with large CB radios coming onto site, what else would corrupt computers memory?

It turned out we had our very own terrorist who the police eventually caught after he went too far and his final act was obviously a terrorist act. After he was caught, he congratulated me on my ability to fault find and correct his acts of terrorism. I was basically following him day by day and keeping pace with his acts from basic instrument calibration changes to disrupting or deleting software. His final act was to set a fire in a panel. He was so frustrated that we had redesigned a solution and I had drawn a new solution which included several ratio speed controls for a drawing machine, that he set the hand drawing on fire and caused a second fire which became obvious now that both fires had been intentional. This was a very dangerous act in the middle of the third biggest petrochemical complex in Europe. That was quite a time. I was on-call with my partner Larry and we both were fixing things at a rapid rate day and night. At the end of this experience I felt qualified to be an engineer and that I could tackle anything the job could throw at me.

My final ICI experience was again a failure of a computer control system. It was not the failure but how we investigated that failure which was special. ICI had developed HazOp and I had a friend Stuart Nunns who used to come to my office and we would strategize about computer incidents and we started collecting data and information. When we had the big hardware failure on the nylon plant that had a software element, we both launched into developing the very first computer HazOp study which became a very big thing. The methodology changed the way we did things and got me involved in the speaking circuit and being involved in computer safety. I started working with the UK H&SE on PES. I starred in a BBC documentary about computer failures; I had to go through media training to be interviewed on this BBC program.

This event led me to leave the UK and move to the United States, working with Honeywell as a Senior Engineering Fellow and the Program Director of the Abnormal Situation Management (ASM) Consortium. The first part was right for my experience and expertise, understanding the problem and defining what an abnormal situation is and what system we have that support normal operations and what is the missing technology and knowledge that leads to abnormal situations. What we discovered was a whole industry around human error as over 80% of incidents were identified as human error.

I worked for almost 10 years with this role then I left Honeywell and formed UCDS as a solution service company for abnormal situations, to improve operator situation awareness and reduce human error. So here I am with almost 20 years in the US working in multiple industries but providing the same service. I have focused on reducing operator error by re-designing control rooms to improve situation awareness, reduce distractions improve communications and collaboration. I have introduced ergonomically designed operator desks/consoles and also the High Performance HMI that allows Alarm Management to actually work and support operator situation awareness rather than overload and overwhelm operators.

This new career has meant getting involved in a whole new discipline of human factors and ergonomics. As well as getting involved in people issues such as work related stress and operator fatigue issues and workload assessment.

I haven’t even touched on many of the other things I have done in my career such as printed circuit board design, computer modeling and the 3 years I had with Davy Ashmore International, or the time as a Power Engineer doing protection systems, installing medium voltage transformers.

One of the questions ISA asked was who should we inform about your award, and as a small business, I could not give them a name, so I guess the readers of my blog will have to be my accountability! I want to thank all the people in my career who I have worked with…

I have to date had such a wide and varied career with so many friends and so many lessons, especially by those who did not have my best interests at heart. Something I have had to learn in business and not just engineering, which has been my hardest challenge in my career. I am grateful to people like John Moscatelli who was the best partner a small business could ask for, or a fellow consultant like David Lee who demonstrated the integrity and work ethic any employer could ever wish for. Both have been good friends and both talented in their own right, and a pleasure to work with bringing their own personality and skills to complement my own diverse background.

I have developed long-term partnerships with Jack Pankoff of Production Excellence Inc., Rob Allen of Lin & Associates, Doug Rothenberg (DRoth), Nick and Lisa to name a few. I am grateful for over 40 years working in industry and hopefully a few more the good Lord willing. For the speaking engagements I have been invited to share some of my experiences, for the book opportunities, magazine articles and great friends like Mark Rosenweig, Walt Boyes, and for the many friends at ISA who have invested time writing standards with me Nick Sands, Paul Gruhn, Donald Dunn, and Maurice Wilkins.

And for friends overseas like Angelo D’Agostino, Mark & Marie Green, Asle Davidsen, Windsor Coles. Thank you to all who have had a positive influence on my life.