Background

Millions of dollars are spent on new plant technology to gain a competitive advantage. In most cases, any advantage that is achieved is short-lived, since others invest in the same technology.

People are the most valuable asset within an organization. However, they are often the most neglected. Strategic operator staffing is the real key to achieving a lasting competitive advantage. If your operators have the proper knowledge and skills, they are able to understand the cause-and-effect relationships between processes. Armed with these competencies, they are able to identify problems before they develop into abnormal situations. They are also able to optimize equipment operation and processes.

UCDS offers a range of services to help you achieve a competitive advantage by obtaining the right people and developing their knowledge and skills.

Service Description

UCDS personnel have extensive experience in assisting plants in improving their approach to hiring and developing operators. Our services include:

- Operator Selection: Assess the current state of your site's operator selection process against industry best practices. An assessment report will be developed to identify areas for improvement and recommendations to improve your selection process. This will ensure that you attract and identify candidates who have the right skills, capability to learn, and have the right personality attributes appropriate to the demands of the job.

- Operator Training and Competence: UCDS can help with your operator training and competence through services that encompass all aspects of Instructional System Design (ISD): analysis, design, development, implementation, and evaluation. These services include:

- Performing Training Gap Assessments that compare your site's program against industry best practices and recommending improvement areas.

- Developing Job Performance Profiles that identify key knowledge, skills, and attributes required for a job position.

- Developing Training and Qualification Management Systems, containing policies and procedures that outline the training program. This management system identifies the training curriculum, training methodologies, and trainer qualifications, as well as providing definitive guidance regarding the conduct and management of the Training and Qualification Program.

- Assisting in the development of training documentation to identify the training completed/needed and are used as the basis for task assignments (never make a person do a job they're not competent to perform).

- Identifying appropriate refresher training, ensuring it is routinely scheduled and conducted.

- Developing systems to ensure training and job competency programs are evaluated on an on-going basis and are changed based on the results of ongoing evaluations.

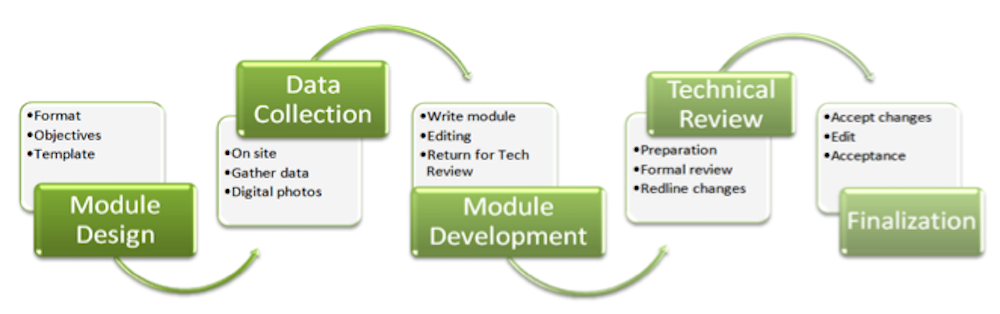

- Assisting in developing training materials that are specific to your operating processes. Our process is a proven development methodology. It incorporates several review steps to ensure the training modules meet the appropriate standards of quality and content. These training materials often include process overview, process systems, and process technology training modules.

Schedule Consultation

Simply fill out the form and we will be in contact with you shortly to schedule a phone or web conference to answer questions and discuss how we can help your organization.

User Centered Design Services provides a full complement of services, including consulting, control room design, HMI implementation, and training services to dramatically improve operations in production facilities around the world.

For additional information, e-mail us at sales@mycontrolroom.com